August 30, 2023

In the ever-evolving landscape of advanced manufacturing, 5-axis CNC machining stands out as one of the finest options available. This cutting-edge technology has revolutionized the way complex parts are fabricated, offering unparalleled precision, efficiency, and versatility. From aerospace components to intricate medical devices, the advantages of 5-axis CNC machining are abundant, making it an indispensable choice for industries seeking the highest quality results.

Why Choose 5-Axis For Your Parts?

-

Multi-Axis Freedom: Traditional CNC machining operates on three axes (X, Y, and Z), restricting the movement of the cutting tool to a fixed orientation. In contrast, 5-axis machining introduces two additional rotational axes, allowing for unprecedented freedom of movement. This means that complex geometries can be machined from multiple angles without the need for manual repositioning, significantly reducing setup times and enhancing overall accuracy.

-

Enhanced Precision: The additional axes of 5-axis machining lead to improved precision and surface finish. By enabling the tool to approach the workpiece from various angles, the machine can maintain optimal cutting conditions, reducing tool wear and minimizing the chances of unwanted vibrations that can affect the final product's quality.

-

Reduced Setup Time: One of the key advantages of 5-axis CNC machining is the reduction in setup time. Traditional machining often requires multiple setups to achieve complex geometries, leading to increased labor and machine downtime. With 5-axis machining, intricate components can be manufactured in a single setup, drastically reducing the time required to bring a product from design to finished parts.

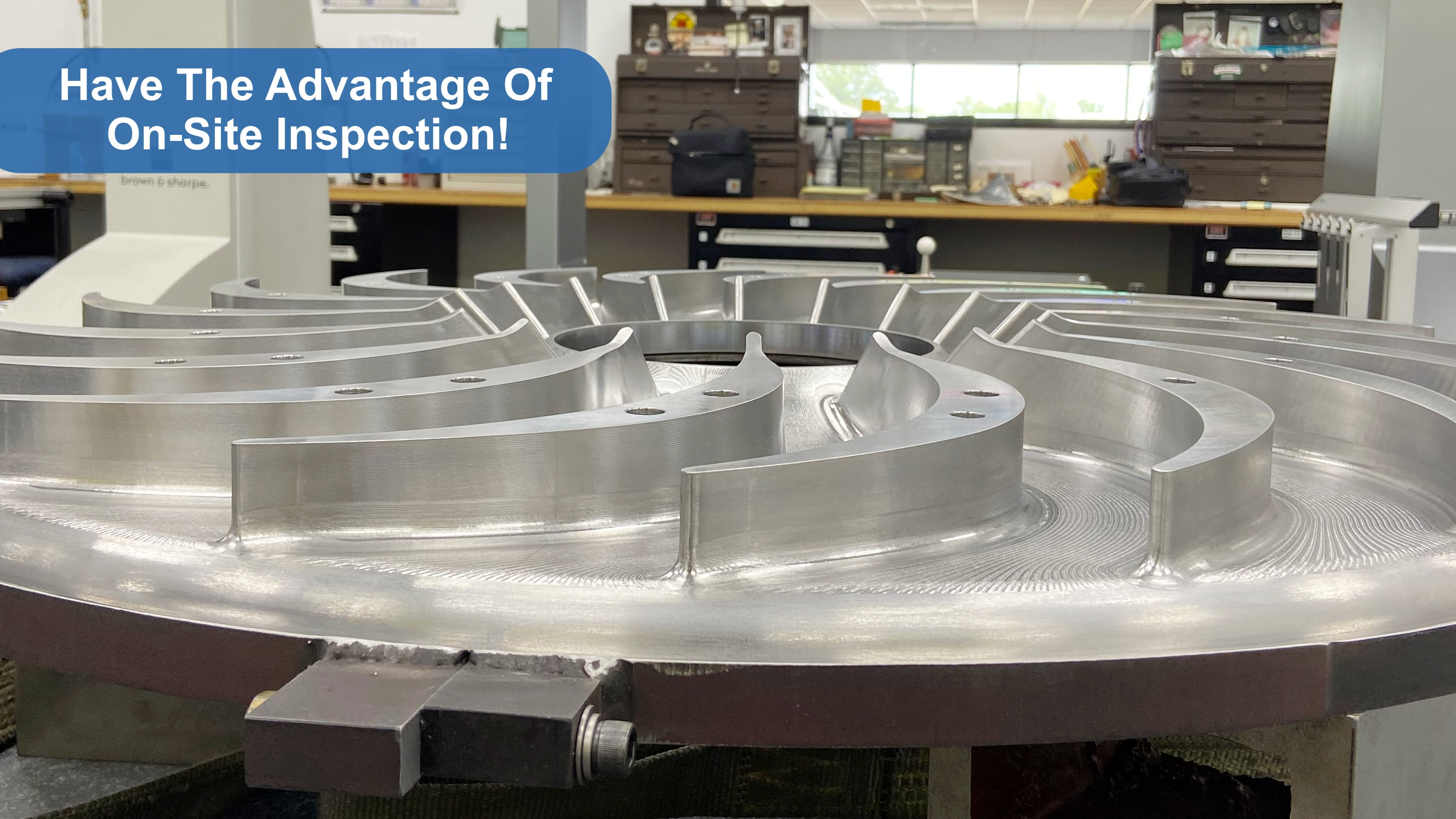

See A Recent 5-Axis Part Made At Precise Tool! -

Complex Geometries: The inherent flexibility of 5-axis machining makes it particularly well-suited for producing parts with complex shapes and contours. Whether it's impellers, turbine blades, or molds with intricate undercuts, 5-axis CNC machines can effortlessly tackle the most intricate design specifications, making it an indispensable tool in industries where precision is paramount.

-

Material Savings: The ability to machine from multiple angles allows for optimized tool paths, reducing material waste. This efficiency not only contributes to cost savings but also aligns with sustainable manufacturing practices by minimizing material consumption and reducing environmental impact.

-

Versatility Across Industries: 5-axis CNC machining finds applications across various industries. From aerospace and automotive to medical devices and consumer electronics, the technology's adaptability and precision make it a go-to choice for creating components that demand the utmost accuracy and reliability.

-

Shorter Production Cycles: The streamlined manufacturing process afforded by 5-axis CNC machining translates to shorter production cycles. Faster turnaround times not only improve customer satisfaction but also allow manufacturers to take on more projects and remain competitive in today's fast-paced market.

In conclusion, 5-axis CNC machining is undeniably one of the best options available for advanced manufacturing. Its ability to achieve intricate designs with unmatched precision, reduce setup times, and cater to a wide range of industries highlights its importance in modern production. As technology continues to evolve, 5-axis CNC machining will likely play an increasingly crucial role in pushing the boundaries of what's possible in manufacturing, enabling us to create products that were once considered unattainable.

Contact Us about your next project, or Request A Quote now!